The Damptec team has recently responded to an urgent enquiry from the owner of an MOT service and repair centre in Bassetlaw, Nottinghamshire.

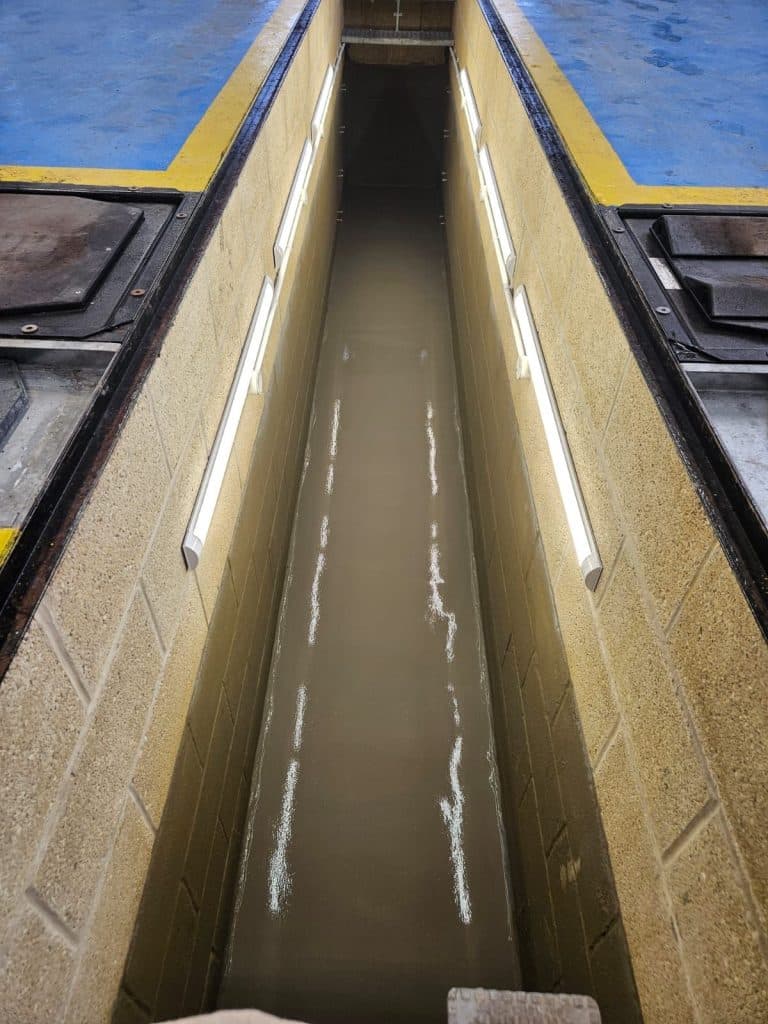

Free water was entering the inspection pit which required a tanking system.

Type A Waterproofing System: Barrier Protection

We recommended Type A Barrier Protection in the form of an internal negative waterproofing system.

Specification

The detail we provided is for use where the requirement is to waterproof a concrete pit.

Materials

- Koster Polysil TG 500 Lime Inhibiter for Concrete

- Reinforcing Tape

- Koster Repair Mortar Plus

- Koster NB1 Grey with Koster SB Bonding Emulsion

Proposed Method in Accordance with Newton Waterproofing Specification

- Horizontal concrete floor to be primed with Koster Polysil TG 500 lime inhibiter for concrete

- Joints and changes of direction: Reinforce static joints with reinforcing tape

- Forma fillet along the wall/floor junctions using Koster Repair Mortar Plus. The membrane should be reinforced at the change in direction from horizontal to vertical with a Repair Mortar smoothing fillet.

- Apply two coats of Koster NB 1 Grey with an additive of SB Bonding Emulsion waterproofing slurry. This is a mineral waterproof coating that contains crystallising and capillary-plugging agents. When these penetrate into the substrate, they develop an intense bond and the capillaries are plugged making it completely waterproof to pressurised water of up to 10 bar.

- Apply Koster SL Premium basement floor self-levelling compound (ready for floor finishes).

The process took 3 working days and our client is very happy with the results allowing MOT testing to resume.